Final Presentation

The final presentation (not a critique session) will take place in the ASL-RedHell, Friday July 29 at 14:00

The presentations should be short and should cover the following:

- Your intentions for the piece

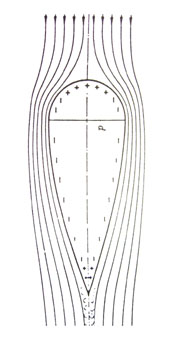

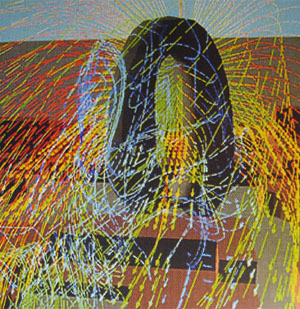

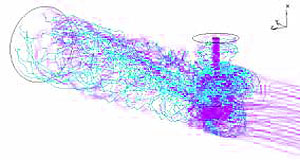

- How you fabricated and textured the piece to affect the flow dynamic

- Any issues of connection from the piece before and the piece after yours

- A conclusion statement.

The presentations will occur in the order of the pieces:

1. Michi

2. Stephan

3. Jenny

4. Sylvan

5. Till

6. Lukas

7. Roman

8. Katrin

9. Sabine

10. Mirjam

After the final presentation we will go outside to the installation, and turn on the water.

This will follow with discussions and critique of the pieces under the real flow conditions.

Once the discussions are over there will be a small apero.

Finishing up:

Wednesday

- posting all images onto the server,

- downloading the video to digital files,

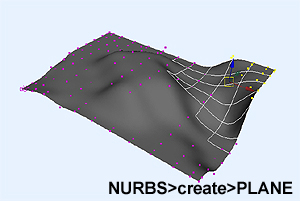

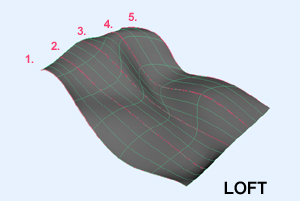

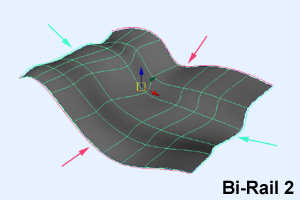

- posting the final MAYA surfaces to the server

- work on final presentations

Thursday:

- construction of installation set-up

- construction of sluice box

- final preparation of presentations

- Retrieval trip to Chur for piece pickup.

- De-forming the pieces and piece touchup.

- Installation setup tests

- Testing of sluice box

- Testing of waterflow

Friday:

- setup and installation of FLOWchannel on-site in front of the HIL building.

- Preparation for presentations

- Presentations begin at 14:00

Final Deliverables:

- Complete documentation in the form of a CD case sized booklet, with text, pictures, and credits.

- Complete DATA CD of all work done in the course:

- projects, scripts, MB, MEL, animations, SurfCAM, presentations, images, and any other media.

NOTE: the CD must be well organized for ease of finding data.