Assignment 2 : Make_it!

The second assignment is intended to give you the opportunity to develop and execute a mini fabrication project using CAAD and CAM technology.

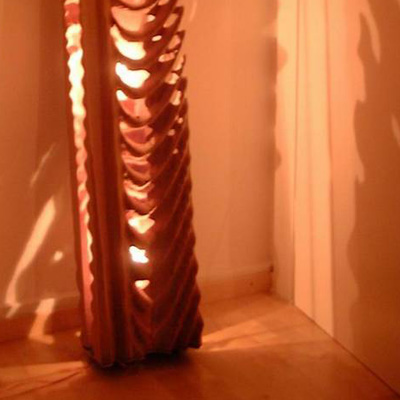

This assignment is set up as a mini-thesis, where each participant is expected to propose an idea for a design that can be manufactured using the CNC Mill. Each project should address the ideas of programmed design, mass customization, or generative design. The final physically manufactured piece is to be considered a version of the programmed design, and a basic "proof of concept".

The idea for the project should come from an area of design that is conceptually

associated with the acts of architecture. such as:

- Industrial Design

- Furniture Design

- Architecture component design

- Art piece

The project should address the technologies of CAAD and CAM and should

be seen as a way of "showcasing" these technologies:

- The conceptual object should be "customizable"

- The object should take advantage of the cutting nature of the mill

o Curvilinear

o Non-standard

o Three dimensional

o Solid

o Cutting paths or patterns

- The object should be simple enough to be programmed

- There should be a logical reason WHY one would want to program it

-

- Concept proposal

- Project development

- Manufacturing

- Documentation

- Presentation

- Concept proposal

The individual proposals should also outline the scope of the deliverables:

- What will the scope of the concept be?

- What will be created digitally?

- What will be manufactured?

- What will be included in the documentation?

- How will the SUCCESS of the project be evaluated?

- A CD sized booklet with explanation, images, and presentation of the project.

- A CD with all the data used to create the project and the final presentation

- A "powerpoint" beamed presentation for the final critique