One day before the extension period expires and the Kuka robot is working non stop. Apart from the opportunity to see the dawn in Schlieren campus, we are more than excited to see the final geometry coming to shape. The team seems to be tuned in the right work-flow…

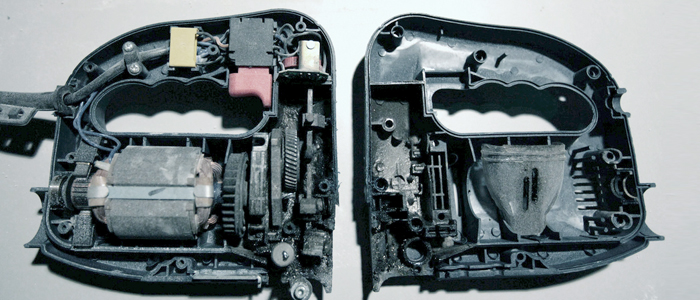

The extension deadline was set a week later and we decided to rationalize the procedure of brick fabrication and assembly. The data for the robot were prepared the least one day in advance, which allowed us to work the Kuka 24 hours per day. The additional 500+ bricks required 100 hours and three jigsaws, the last one still in order today.

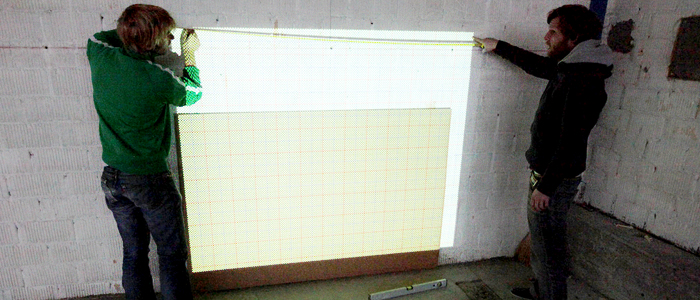

The manual labor was the key for this setup. Most of the students reorganized in teams of assembly, creating new parts from scratch or repairing previous ones. For the eight pieces to come together, a new floor plan was cnc cut and laid out in Schlieren, and the pieces were fixed in specific positions on pallets. Fitting such an off-the-grid geometry was very challenging and required substantial effort as well as some technical expertise. Tom Pawlofsky was the person with the right answers who very kindly offered his assistance.

Digital Production brought to the table some more analogue techniques: drawing sections on projected images