|

designtoproduction • profile • team • awards and publications • how to find us | |||||

|

|||||

|

Inventioneering Architecture Exhibition platform California College of Arts and Crafts (CCAC) San Francisco 2005 Awarded with the Holz21 Prize 2005 Client ETH Zürich Executive Board Prof. Dr. Gerhard Schmitt, Prof. Dr. Marc Angélil Design and Organisation Instant Architects Zürich/Berlin Dirk Hebel and Jörg Stollmann with Sascha Delz Geometry Consulting and Engineering caad.designtoproduction ETH Zürich Christoph Schindler, Markus Braach, Fabian Scheurer CNC-Production Bach Heiden AG Heiden (CH) Franz Roman Bach, Hansueli Dumelin << back |

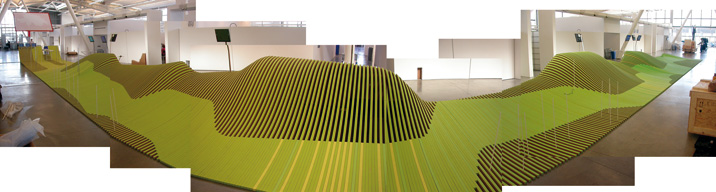

"Inventioneering Architecture" is a travelling exhibition of the four Swiss architecture schools (Zurich, Lausanne, Geneva and Mendrisio) that was first shown at the California College for Arts and Crafts (CCAC) in San Francisco and is now touring the world. For this project the office Instant Architects in Zurich designed a stage, which resembles an abstract crosscut through Swiss topography. This doubly curved platform measures 40 by 3 metres with varying heights up to 1.5 metres. A footpath meanders along the surface, passing the exhibits. In order to meet the budget requirements, we proposed to assemble the hilly platform from 1000 individually curved rafters that were milled out of 40mm medium density fibreboard (MDF). They are assembled in comb-shape, so that their overlapping sections form the closed surface of the path while the exhibition area is marked by gaps. By choosing a rather cheap material and implementing a continuous digital chain from the definition of the surface geometry in the CAD soft¬ware Maya until the control of the five-axis CNC-mill that the parts are manu¬factured with, production costs could be lowered significantly. The detailing was developed closely after the capabilities of a five-axis router. The platform is divided into 40 millimetre wide cross sections, each describing the upper surface path of one rafter. The milling tool follows this path and rotates around it at the same time, cutting out a so called "ruled surface" that follows the topography of the platform both along and across the section. Thus it is possible to manufacture a three-dimensional, doubly curved surface from two-dimensional sheet material at very low cost. The rafters are connected by dowels and supported by perpendicular boards. Since the structure consists of roughly 1100 individually shaped parts, the crucial point was to automate the translation of the platform geometry into the geometry of the single parts and finally into the steering code for the computer controlled mill. This was accomplished by a set of scripts in the CAD-package Vectorworks. The first script imports the original design defined as a NURBS-surface in the modelling software Maya, reads the coordinates of the platform’s cross-sections for every rafter and determines the angles of bank. A second script translates this information into the milling paths for all 1000 rafters, also including all drillings for the dowels. A third script arranges and optimises the rafters on the MDF-boards and generates the so called G-Code, the programs which control the five-axis CNC-router. 120 MDF-boards sized 1.0 by 4.2 metres were used to fabricate all rafters within roughly 50 milling hours. |

||||

|

Revision r1.16 - 20 Aug 2006 - 11:55 - ChristophSchindler Parents: WebHome |

|