M2:W2(Nervous System): Final Assignment

We had to design three 3d-printable cups using reaction diffusion.The three designs had to be聽substantially different from each other.The maximum dimensions of each cup were聽6x6x8cm. The minimum wall thickness is聽1.6mm聽. Possible ways to make a 3d-printable cup :聽time extrusion sketch,3d reaction-diffusion sketch,聽mesh based reaction diffusion.To generate a cup shape with these methods we had to find the ways to constrain our reaction to a cup-like shape 聽for instance:聽changing f,K through space and/or time,changing the diffusion rates through space and/or time,changing the initial conditions,remove concentration in certain locations to create a void,distort a RD mesh.

STUDENT WORKS

Jesper Th酶ger Christensen

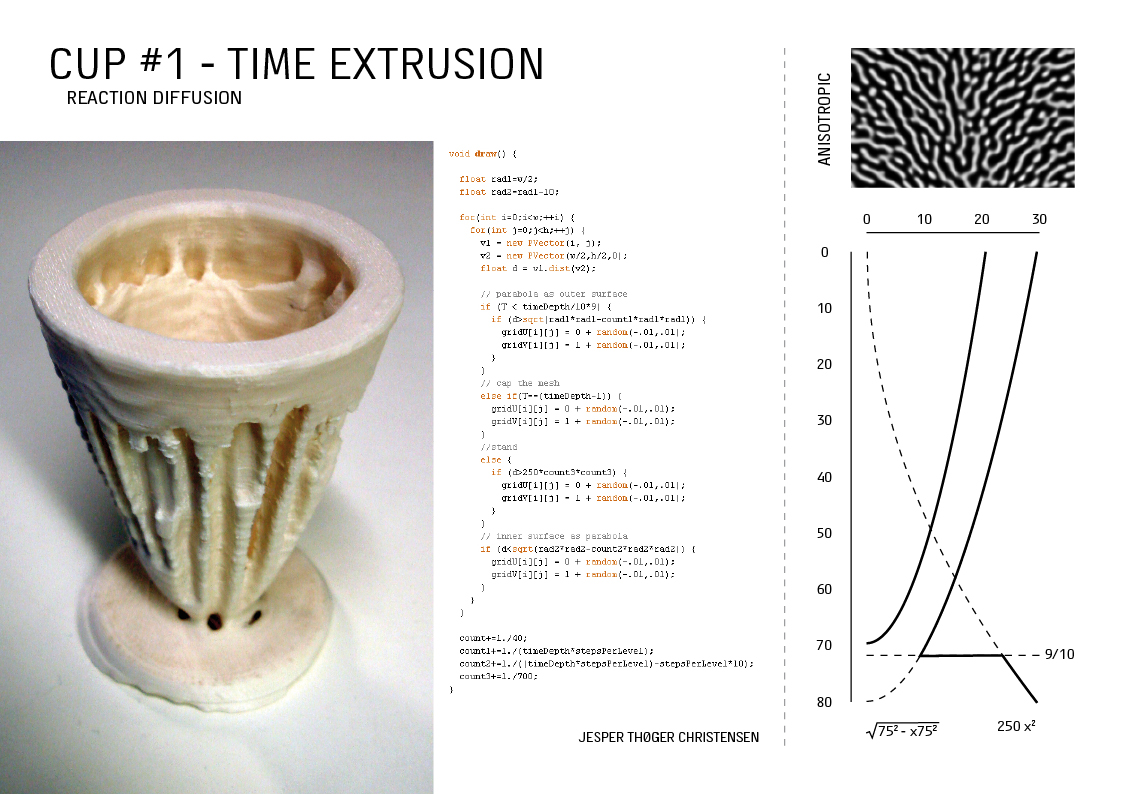

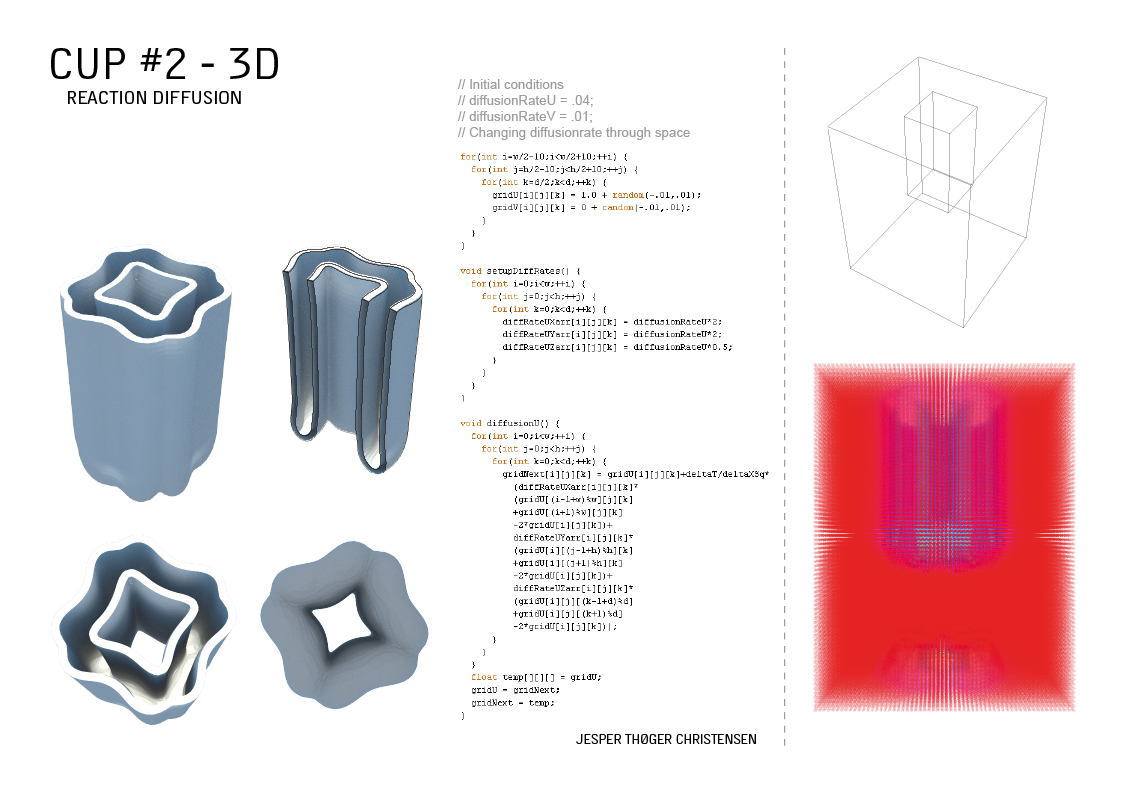

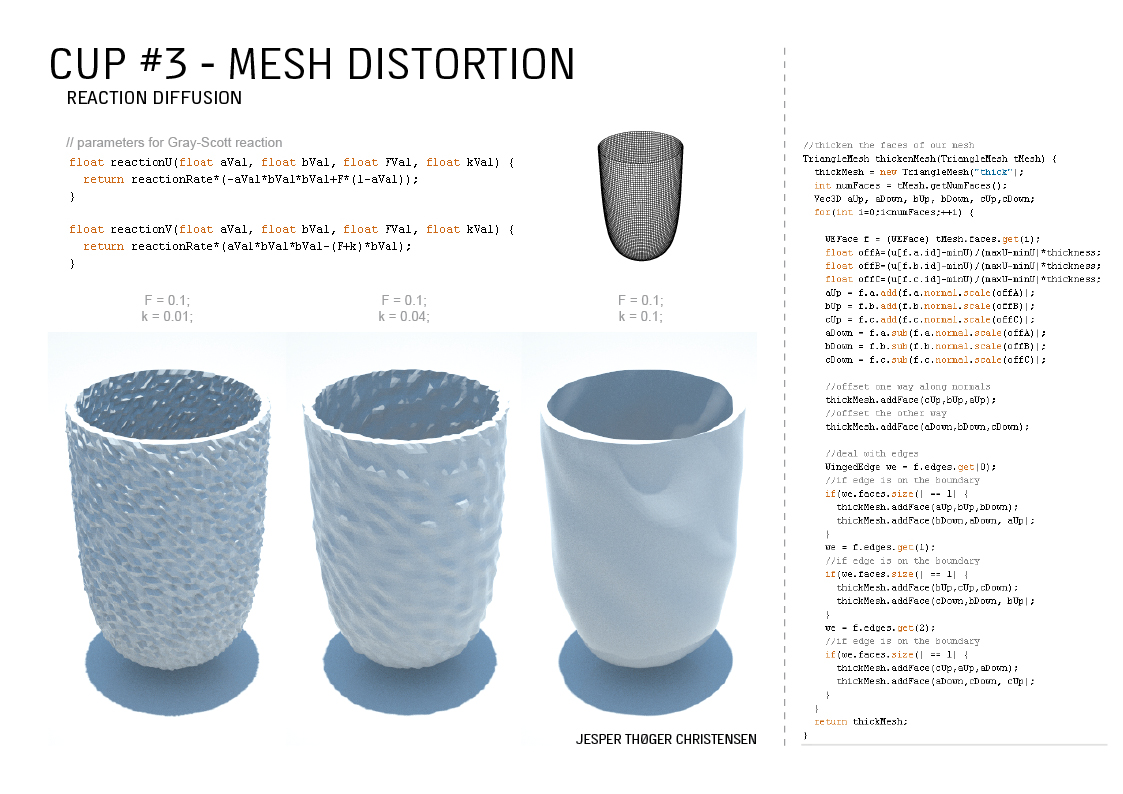

Final task of the workshop with Nervous System was to design three 3d-printable cups using reaction diffusion.I used the following 3 techniques developed through the workshop to constrain the reaction to a cup-like shape. All using the Gray-Scott Reaction.

CUP #1 臇 Time ExtrusionIntroducing anisotropic diffusion of chemical u by having different diffusion rates in the x and y directions to create asymmetry.F and k parameter of reaction are changing through space.Controlling mesh generation by continuously restraining reaction-diffusion to happen within a set of law curves defined by mathematical formulas. Actually constantly controlling the concentration of the two chemicals to create void or solid.

CUP #2 臇 3D聽Setting up an initial concentration of the two chemicals within a box to start the reaction-diffusion.Diffusion of chemical V is fixed. But the diffusion rate of chemical U changes through space so that it diffuses 2 times faster than V in the X and Y direction but diffuses with the same rate as V in the Z direction.

CUP #3 臇 Mesh DistortionDistorting a regular mesh of a cup by using information from a Reaction Diffusion simulation to modulate the mesh.Diffusion rate of chemical U is 4 times faster than chemical V3 cups are generated by using different parameters for F and k in the equation of the Gray-Scott Reaction

Magda Osinska

Agata Muszynska

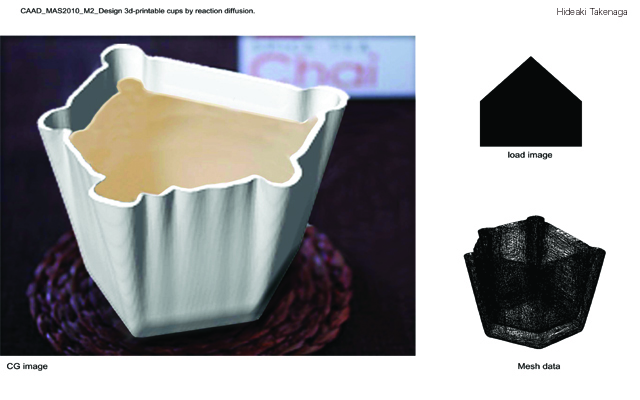

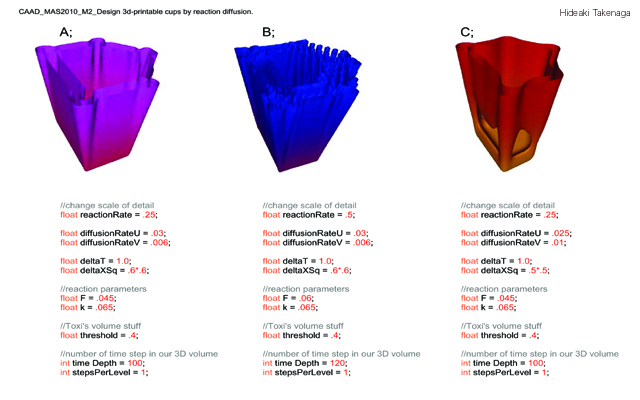

Hideaki Takenaga

Nikola Marincic

These three projects conclude the workshop with Nervous System. The final assignment was about making an industrial product (cup) using forementioned processes. First design is a cup, where the RD on a 3D mesh object is used for forming the outher shell of a cup. For the second and third design RD processes growing in 3D were used to make a different rounded shapes. These specific shapes were based on the specific RD parameters that were chosen because they give the rounded half closed forms – suitable for storing things. Second design is a combination of an aquarium and flower vase, and the third design is a spatial instalation that shows the creative potential of using these volatile processes.